Technical Criteria and Practical Applications Based on the Experience of Matrix Injection Moulds

The use of electric motors integrated into plastic injection moulds is experiencing sustained growth. This is not a short-term trend, but rather a technological evolution driven by the need for greater control and precision in demanding production environments. This evolution affects multiple sectors, with particularly strong adoption in the medical, pharmaceutical and cosmetic industries.

In these applications, servo-electric systems directly replace hydraulic and pneumatic cylinders, eliminating components from the mould that rely on fluids. This substitution is not only a technical advantage, but in many cases a mandatory requirement to meet cleanroom standards.

From a functional standpoint, electric servo actuation allows mould movements to be controlled through closed-loop position control, programmable speed profiles and torque management—capabilities that are difficult to achieve with conventional hydraulic systems.

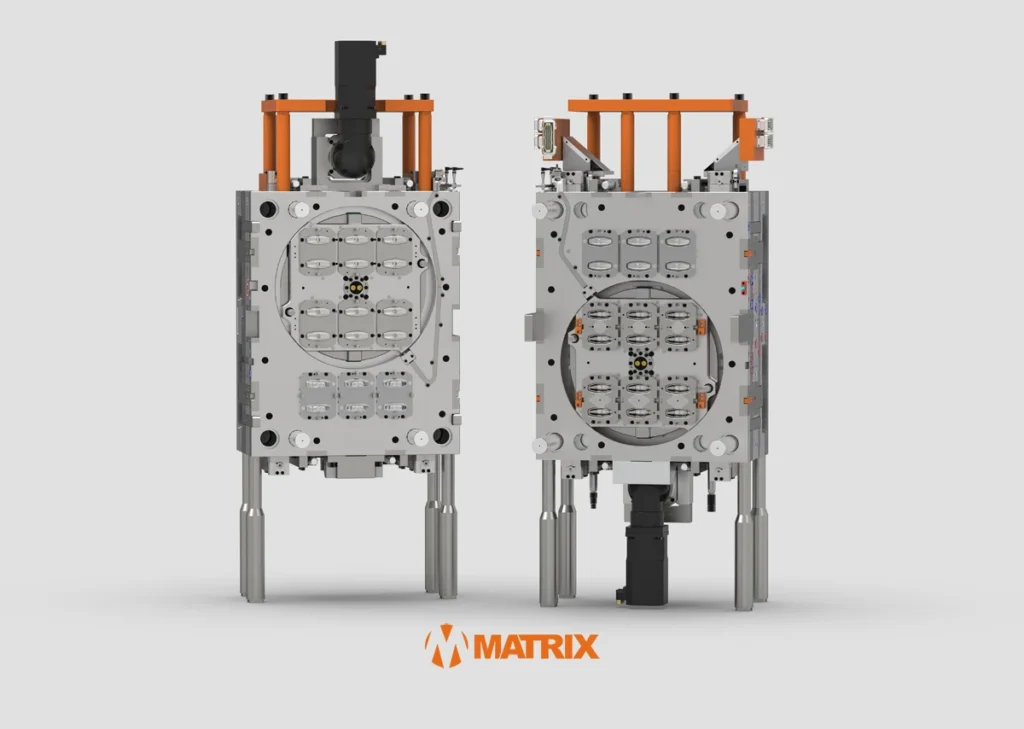

At Matrix Injection Moulds, this technology represented a paradigm shift as early as the early 2000s, when it was first applied to the actuation of slides in moulds for the cosmetic industry, replacing hydraulic actuators with electric systems.

Since then, servo-electric solutions have been systematically incorporated into projects where the process requires precise motion control, programmable sequences or simply the elimination of hydraulic circuits for reasons of cleanliness, process stability or reduced maintenance.

Technical Advantages of Using Servo Motors in Injection Moulds

The use of servo motors provides clearly identifiable benefits from both a technical and process perspective:

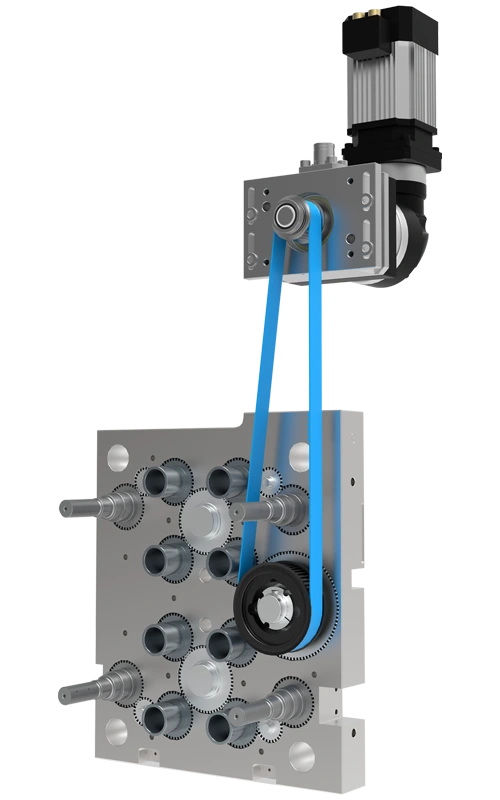

- Precise position control and high repeatability, independent of temperature variations or system wear.

- Motion programming through adjustable acceleration and deceleration profiles without mechanical intervention.

- Cycle time reduction by optimising motion paths and eliminating unnecessary inertia.

- Elimination of oil leakage risks, critical in sensitive production environments.

- Ability to perform movements during or after injection, expanding the functional capabilities of the mould.

- Reduced maintenance compared to hydraulic systems, due to fewer wear-prone components.

- Full compatibility with ISO cleanrooms, both by design and in operation.

- Capability to produce different part versions within the same mould by configuring the unscrewing stroke using a single servo motor.

Typical Servo Actuation Applications in Moulds

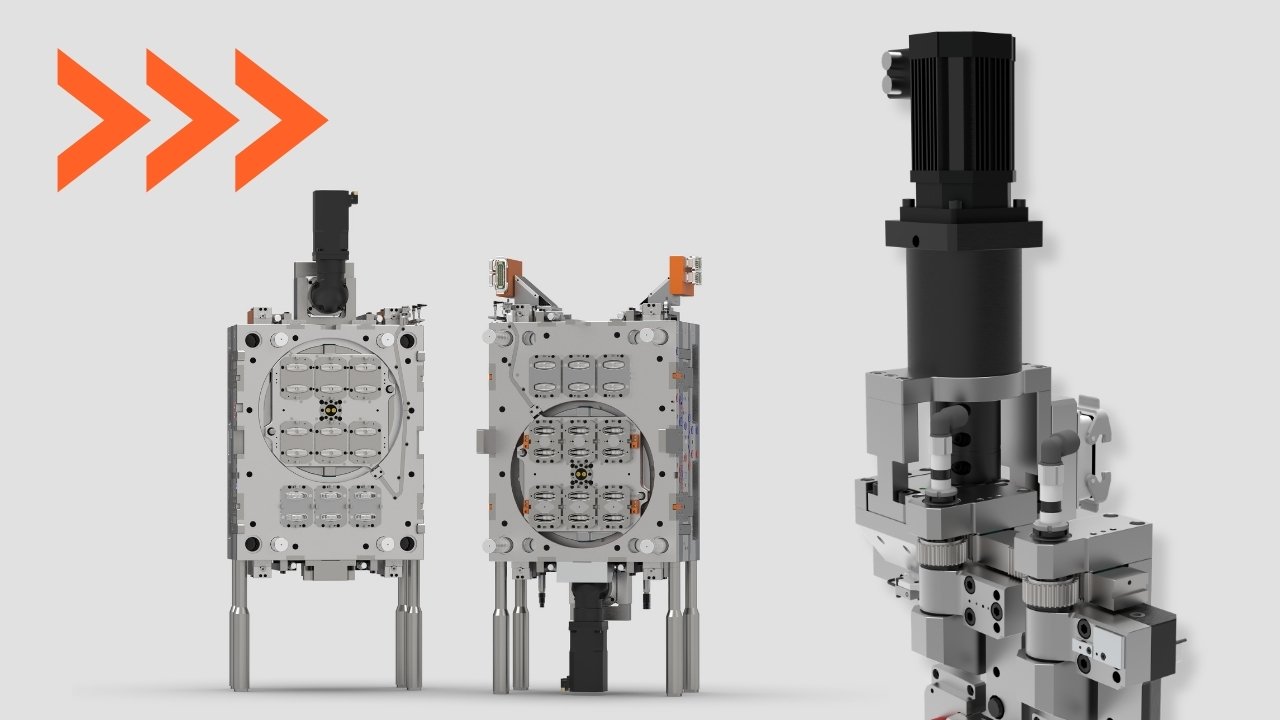

At Matrix Injection Moulds, servo motors are mainly applied in:

- Servo actuation of slides and internal cores.

- Unscrewing systems for threaded cores.

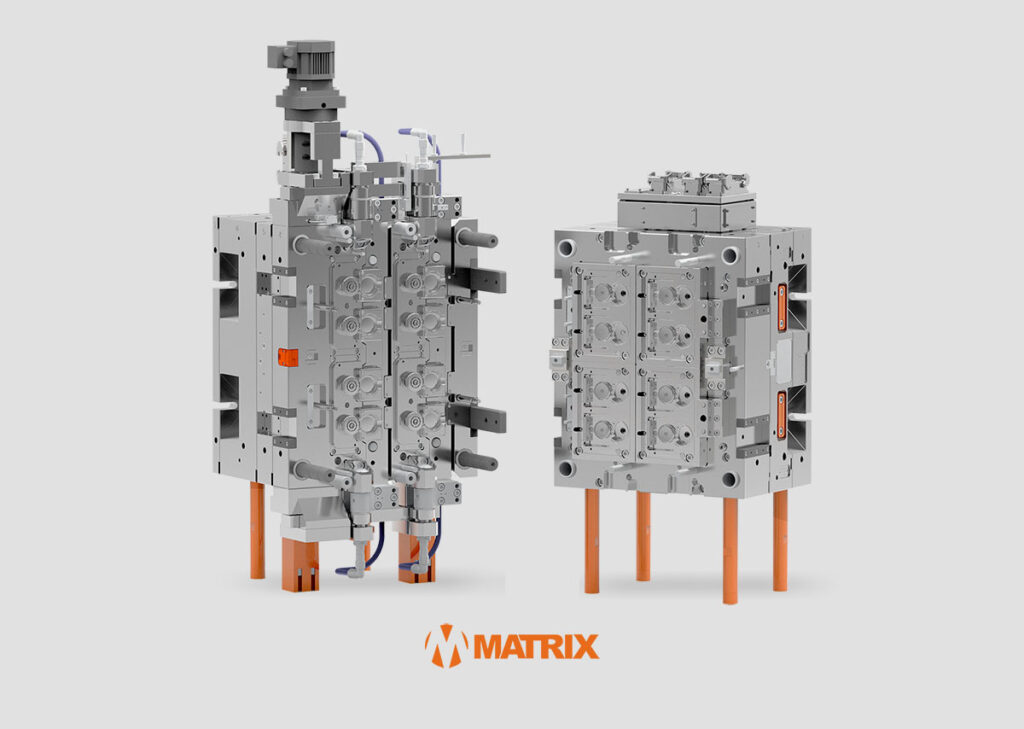

- Movement of index plates or rotary mechanisms.

- Programmable movements for in-mould assembly

(IMCA – In Mould Cavity Assembly). - Closing movements for high-speed flip-top systems

(IMCC – In Mould Cavity Closing).

In conclusion, the use of servo motors in injection moulds is part of a broader trend: the progressive integration of sensors and electronic components into tooling, transforming the mould into an active, controllable system. In this context, the combined mastery of precision mechanics and mechatronics is decisive for the development of moulds that meet current industrial standards.